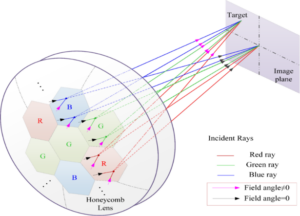

Topological Design

Using topological optimization and reverse ray-tracing, we are developping algorithms for automated design of micro-lens arrays (MLA). The range of application is very wide (micro-fluidics, lab-on-chip, augmented reality, lithography, etc.). One of our significant designs, is a perfectly achromatic imaging MLA published in Optica. This design can focus multi-colored light onto much narrower spots than conventional systems, while requiring only a single optical component (instead of at least 2 or 3). This improves productivity (less complexity in manufacture/assembly) and sustainability (less use of materials/energy).

Tool Path Planning

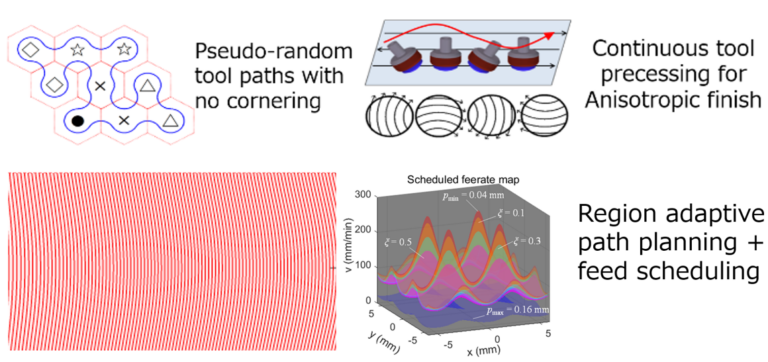

Unlike cutting, in which material removal is position dependent, in many finishing processes such as compliant grinding and polishing, material removal depends on the tool in-feed. This similarity with certain additive manufacture processes (e.g. directed energy deposition) requires specialized tool path generation algorithms. We have developed several original methods for tool control including:

- A patented pseudo-random tool path method to reduce light-interference induced by repeating waviness.

- A continuous tool precessing motion that produces anisotropic surface roughness (Ra < 0.2 nm).

- Numerous tool path planning and feed scheduling algorithms for finishing complex freeform surfaces.